Optional greenhouse equipment and functions

1. Natural ventilation to cool down:

Using the basic principle of hot and cold air convection, hot air flows upwards and cold air flows downwards. It is exhausted from the top ventilation window, and cold air enters from the side ventilation window to form convection, so that the temperature of the greenhouse is naturally lowered.

2. Forced ventilation and cooling:

A cooling pad is installed on the heat exchanger of the greenhouse, and a high-power low-noise exhaust fan is installed on the other side. The basic principle is that the water molecules absorb the volume in the air during the evaporation process, that is, the water molecules of the cooling pad flow in the direction of the exhaust fan under the action of the exhaust fan. During the flow, the water molecules evaporate, absorb and transfer to cool the greenhouse. Its temperature can reach 3 to 6 instants

3. Circulating fan:

The most effective distance between the cooling pad and the fan is 30 to 50 meters. If the distance exceeds 50 meters, the circulating fan should be used to transmit in the middle to increase the cooling effect.

The reasonable arrangement of the circulation fan can make the humidity of the air in the greenhouse uniform, and at the same time can make the green leaves of plants oscillate, effectively promoting the better growth of green leaves of plants.

4. Central air-conditioning:

Under special requirements, such as scientific experiments or specific environmental requirements, a central air-conditioning system can be installed to ensure precise control of the temperature in the greenhouse to achieve the purpose of both cooling and heating. This can be achieved by using chillers or air source heat pumps.

5. The warming of the greenhouse:

In relatively cold areas, when the outdoor temperature in winter is low to a certain temperature, when the temperature in the greenhouse does not reach minus 10 to 15 degrees Celsius, plants will stop growing or even freeze to death. Therefore, in colder areas, the greenhouse needs to be heated. The heating method is based on the specific local conditions, and the economical and applicable method is selected. It is usually more economical to have coal, gas, or oil-fired boilers for heating. It can also be directly heated by electricity, such as central air conditioners, electric heating panels, electric heaters or electric boilers, as well as commonly used hot blast stoves, ground source heat pumps, air heat pumps, etc.

6. External shading:

The strong light of the sun can quickly increase the temperature in the greenhouse. At the same time, in order to better cool down the greenhouse, it is necessary to install an external shading system to effectively avoid the sun's strong light, and achieve the purpose of preventing the temperature in the greenhouse from being too high.

7. Internal shading:

The internal thermal insulation system can not only avoid strong sunlight, so that the plants in the greenhouse will not suffer strong damage, but also can play a role in reducing the temperature in the greenhouse. In winter, it also cuts off the convection of hot and cold air up and down, and plays a role of heat preservation.

8.Special roller bench for greenhouse:

The characteristics of ordinary roller bench and mobile roller bench are:

1. Generally used for flower production, vegetable seedlings, scientific research greenhouses, flexible use and rapid turnover.

2. The planting operation is convenient, and the anti-rollover device is designed to avoid overturning.

3. A 0.6m-0.8m wide working channel can be created between any two roller bench.

4. It can be moved left and right for a long distance, and the height direction can be fine-tuned. The greenhouse area can reach more than 80%.

5. The mobile seedbed also has the advantages of flat mesh surface, firm welding, good load-bearing capacity, accurate size, convenient installation and construction, corrosion resistance and durability.

6. Beautiful appearance, economical and practical, corrosion resistance, anti-aging, acid and alkali resistance, and non-fading.

The bed surface of the tidal seedbed is composed of tidal panels, with special doors for upper and lower water outlets, which can be used for root irrigation and integration.

The characteristics of tidal roller benches:

1. Tidal irrigation has a water-saving, completely closed system cycle, which can achieve more than 90% of water and fertilizer utilization;

2. Tidal irrigation crops grow fast, and the weekly seedling age can be at least 1 day earlier than traditional seedling raising methods. The utilization of facilities is improved;

3. The tidal irrigation method avoids the production of water film on the leaf surface of plants, so that the leaves receive more light and photosynthesis, and promotes transpiration to absorb more nutrients from the roots;

4. Tidal irrigation can provide stable roots The moisture content of the substrate prevents the capillary roots from dying due to drought near the sides and bottom of the container;

5. Tidal irrigation makes the relative humidity easy to control, can keep the crop leaves dry and reduce the use of chemicals;

6. The tidal irrigation cultivation bed is very dry, no weeds grow, and can reduce the growth of fungi;

7. Tidal irrigation can reduce the growth of fungi. The management cost is reduced. Even if the nutrient solution is managed by manual operation, one person can complete the irrigation of 0.2h㎡•about plug seedlings within 20-30min;

8. Tidal irrigation can be used at any time, regardless of varieties, specifications, time limit.

9. Greenhouse irrigation system:

Fixed sprinkler irrigation: The fixed sprinkler irrigation has the advantages of simple construction, low cost, and convenient installation. It can be directly constructed on the original greenhouse structure without the need for a separate frame structure.

Mobile sprinkler irrigation: The structure is more complex and requires an independent frame structure. Compared with fixed sprinkler irrigation, it is more flexible. It can be separately irrigated and fertilized according to the different needs of crops.

It is suitable for greenhouses with large areas and many types of crops.Drip irrigation: labor saving: the drip irrigation system only uses manual or automatic control to open the valve, combined with fertilization, which greatly saves labor input and reduces planting costs. Water saving: drip irrigation is a whole pipeline water delivery, low pressure system, local humidification, water leakage and loss are minimized. Fertilizer saving: drip irrigation can be conveniently combined with fertilization, and the fertilizer can be directly and evenly applied to the root system of the crop, which greatly improves the utilization rate of fertilizer

10. Fertilization system:

Automatic fertilizer applicator: It belongs to the technical field of agricultural machinery. The technical problem to be solved is to provide an agricultural automatic fertilizer applicator that can control the amount of fertilizer applied and apply uniformly without energy consumption. The technical solution is that it is composed of a fertilizer bin, a feed port, a feed port, an impeller, a transmission shaft, a material shifting device, and a support. The feed port and the discharge port are located above and below the fertilizer bin, and the impeller consists of multiple The blades are formed around the central shaft sleeve of the impeller.

The central shaft sleeve of the impeller is tightly connected with the transmission shaft. The material shifting device corresponds to the discharge port. The fertilizer bin, the impeller and the transmission shaft are installed on the bracket. In this automatic fertilizer applicator, under the impact of the water flow, the impeller drives the shifting device to pull out the fertilizer at the outlet of the fertilizer bin. By controlling the speed of rotation of the impeller and moving the shifting device and the position of the stopper device, the outlet of the fertilizer is adjusted. To achieve the purpose of controlling the number of fertilization and uniform fertilization.

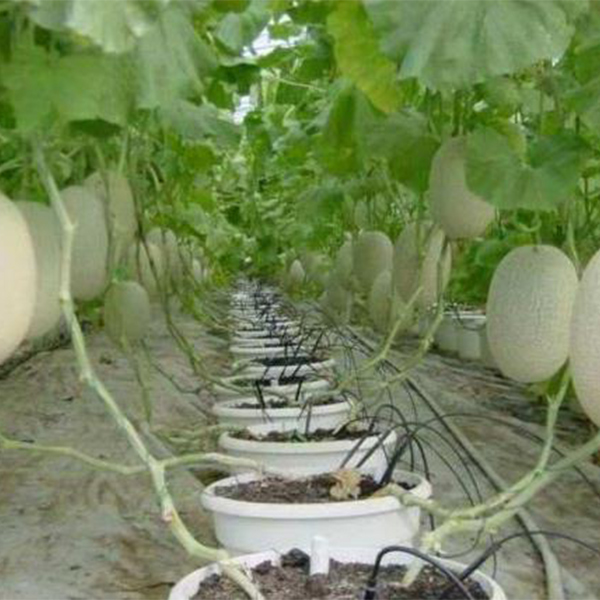

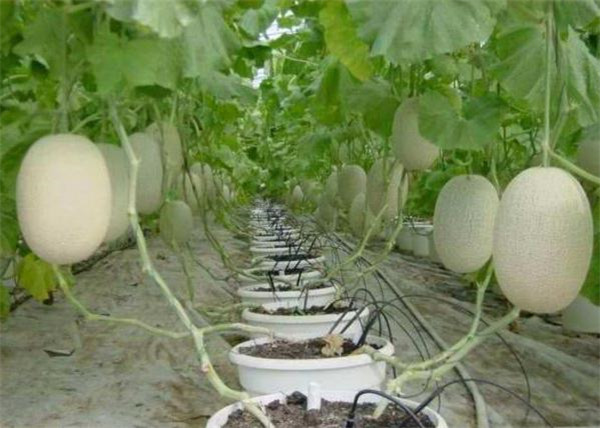

11. Planting equipment

Soilless cultivation: Soilless cultivation refers to a cultivation method that uses other substances as a source of nutrients and fixes plants without using soil, or only uses a substrate during seedling cultivation, and uses nutrient solution for irrigation after planting. Soilless cultivation has the characteristics of saving fertilizer and water, saving labor and labor, resisting diseases and insects, high yield and high efficiency, and environmental protection. It is a new technology developed in recent decades. In recent years, the ornamental greenhouse has demonstrated the cultivation mode of modern and efficient agriculture.

The collocation and application between vegetables and related hard landscapes and garden ornamental plants reflects the diversity and ornamentalness of modern vegetable varieties; choosing a variety of cultivation modes to display the vegetables reflects the diversification of modern vegetable cultivation modes. Demonstrates the science and education of modern agriculture.Three-dimensional cultivation: vertical tube cultivation. A cylinder tube or a plastic tube is arranged on the ground, and a number of planting holes are distributed on the ground, and crops are planted in the holes.

Multi-layer bed cultivation. Multi-layer parallel planting beds are set up in the greenhouse, and crops are planted on the beds and cultivated with nutrient solution.

Slope planting bed cultivation. A herringbone planting bed is set in the greenhouse, and crops are planted on the bed.

Mobile three-dimensional cultivation.

12. Automatic control system

The greenhouse control system is an environmental automatic control system specially developed and produced for agricultural greenhouses, agricultural environmental control, and meteorological observation. It can measure wind direction, wind speed, temperature, humidity, light, air pressure, rainfall, solar radiation, solar ultraviolet, soil temperature and humidity and other agricultural environmental factors. According to the growth requirements of greenhouse plants, it can automatically control window opening, film rolling, fan cooling pad, biological Environmental control equipment such as supplemental light, irrigation and fertilization automatically regulates the environment in the greenhouse to reach a suitable range for plant growth and provide the best environment for plant growth. The greenhouse control system can make the greenhouse operate in an economic and energy-saving state, realize the unattended automatic operation of the greenhouse, and reduce the energy consumption and operating cost of the greenhouse. This system has become the domestic advanced greenhouse environment control system so far

Production workshop

Exhibition

Shipment

Certificate

FAQ

1.Which information do you need to send in order to get a quotation?

You should provide us the next information:

-Your country.

-Highest and lowest temperature

-Highest wind speed.

-Snow load,

Size of the greenhouse (width, height, length)

What will you grow in the greenhouse.

2.How much guarantee time do you offer for the products?

Greenhouse overall free guarantee for I year, structure guarantee

for 10 years and for each equipment don't hesitate to ask.

3. How much time do you spend producing my greenhouse?

we spend between 20 and 40 work days making your greenhouse after receiving 30% deposit.

4. How much time does it take to the greenhouse to arrive to my country?

It depends, as you knew we are located in China, so the shipment by sea would take between 15-30 days. For air shipment, it depends of the size on if just are some equipment. It’s possible to receive

through air and it will take between 7-10 days.

5. Which material do you use?

For structure, usually we used hot galvanized steel pipe, it's the best steel material, can be used for 30 years without rusting. We also have galvanized steel pipes and steel pipes as options. For coverage,

vwe have high quality plastic film, polycarbonate sheet and glass with different thickness.

6. How can you show me my greenhouse before starting to produce it?

We offer free design drawing, professional chargeable drawing for engineering seal. And also when we sign the contract we send you the production and installation drawings.

7. When my greenhouse arrive how I'm going to start building it?

There are two options, the first, we send you the production and installation drawings that are understandable for engineers, and the second, we can send the engineer to guide the construction, also can send construction worker team, so you don't have to find worker in location. But you need to be responsible for their visa, Airfare, accommodation and security insurance.